深圳市新松衡力自动化设备有限公司

联系人:莫先生 13510839855

业务:刘振鑫 18076545681

业务:柴津津 15112331270

电话:0755-28121215

传真:0755-28121315

邮箱:sinsoholly@163.com

QQ:2129524050 3188820898

网址:www.szxshl.com

地址:广东省深圳市龙华区大浪南路河背工业区河盛文创园402-403

深圳市新松衡力自动化设备有限公司

联系人:莫先生 13510839855

业务:刘振鑫 18076545681

业务:柴津津 15112331270

电话:0755-28121215

传真:0755-28121315

邮箱:sinsoholly@163.com

QQ:2129524050 3188820898

网址:www.szxshl.com

地址:广东省深圳市龙华区大浪南路河背工业区河盛文创园402-403

1、在焊接过程中,锡丝里面的助焊剂过少,会使烙铁头表面氧化速度加快,尤其是水溶性助焊剂在高温的时候极具腐蚀性,也会损坏烙铁头;

2、自动焊锡机锡丝不纯或是含锡量太低;

3、温度太高,尤其是温度超过400℃的时候,极易使吃锡面氧化;

4、用于清洗烙铁头的海绵含硫量过高,太干或太脏,也会对烙铁头有影响;

5、自动焊锡机烙铁头接触到诸如塑胶,润滑油或是其他化学物,引起氧化作用;

6、使用时吃锡面没有全部加锡。

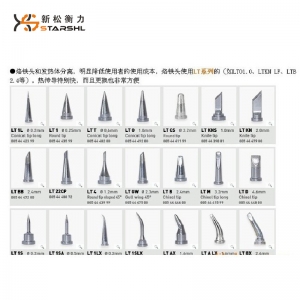

在自动焊锡时,烙铁头的型号和选择一定要选择合适。烙铁头选择不正确,不但会影响自动焊锡机的效率,而且焊接的质量也会大大降低。

手机:13510839855(莫先生)

电话:0755-28121215

邮箱:sinsoholly@163.com

网址:www.szxshl.com

地址:广东省深圳市龙华区大浪南路河背工业区河盛

文创园402-403

|  |

| 手机站 | 关注公众号 |